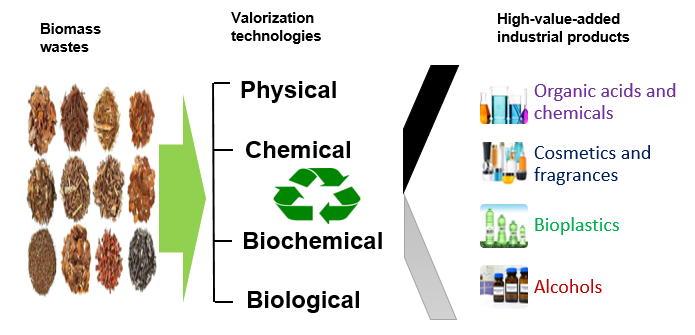

Graphical abstract

Introduction

The increasing amount of biomass wastes which has led to serious environmental issues, coupled with unstable petroleum resources have prompted the need to explore the conversion of biomass wastes into value-added chemicals. About 100 billion metric tons of biomass waste material are produced yearly all over the world (Cho et al., 2020). Biomass waste includes a diverse range of materials such as municipal solid waste (MSW), forestry residues, agricultural wastes, fruit processing waste, and waste from other food processing industries (Zhou and Wang, 2020). Majority of these wastes are left in the field to decompose naturally, discarded in landfill space, or burned in the open for cooking, drying, and charcoal production, which not only has low efficiency but also causes significant environmental pollution such as greenhouse gas emissions and air quality deterioration. Hence, establishing an environmentally friendly and efficient strategy for utilizing and managing different kinds of biomass waste by converting them into high value industrial products for various medical, industrial and environmental applications is paramount. Biomass waste is expected to generate 20% of transportation fuels and 25% of industrial chemicals by 2030 (Clauser et al., 2021).

Although, several approach such as physical, chemical, and biological techniques towards valorization of biomass waste have been explored and shown successful degradation over the year, they still have their shortcomings. Biological approach particularly enzymatic deconstruction has the potential to replace the current techniques adopted and generate higher yields, greater selectivity, and reduced costs, as well as the production of fewer inhibitory byproducts (Cho et al., 2020).

This mini review summarizes the different types of biomass waste, various technologies employ in their valorization, and the types of high-value-added industrial chemicals derived from the wastes.

Chemical constituents of biomass waste

Biomass wastes can emanate from variety of sources namely; municipal pruning, agriculture and forestry, food and fruit processing industries, wood industries etc. These biomass wastes comprise of intricate matrix of three main constituents namely cellulose, hemicellulose and lignin, which must be broken-down to acceptable product yields (Clauser et al., 2021). Other components associated with biomass are lignin, collagen, gelatin, keratin, chitin, xylan, glucan etc.

Cellulose is the most ubiquitous polymer, accounting for 40-50% of all plant and woody biomass by weight (Zhou and Wang, 2020). It is the biomass skeleton, and the protective layer is lignin. To form a lignin-carbohydrate complex structure, they are linked together by covalent bonds and non-covalent hydrogen bonds (Yin et al., 2021). The lignocellulosic matrix is formed by the strong bonding of these three components. As a result of the physical and chemical complexity of the constituents, efficient measures must be taken to fully expose the cellulose structure, increase cellulose effective contact with reactants, and enhance the conversion rate of biomass (Zhang et al., 2020). Hemicellulose is hydrogen-bonded to cellulose and covalently linked to lignin. Lignin is the main structural compound in the formation of plant cell walls, particularly in wood and bark due to its aromatic structure, which increases strength and rigidity. Lignin may have varying physicochemical properties depending on the type of biomass and extraction technique (Zhou and Wang, 2020). It acts as a protective shield for cellulose microfibrils, causing cellulose hydrolysis to glucose difficult. Furthermore, the lignin-hemicellulose link inhibits the deconstruction of cellulose microfibrils to pentose and hexose sugars. As a result, lignocellulosic biomass (LCB) requires optimal pretreatment to remove the highest lignin content and degrade the cellulose into simple sugars via saccharification so that fermentative microorganisms can produce the most amount of targeted industrial chemicals (Clauser et al., 2021).

Valorization of biomass waste into high-value-added industrial chemicals

The concept of bio-converting waste resources into more valuable industrial chemicals and/or products is known as waste valorization (Gumisiriza et al., 2017). The various aforementioned waste materials can be converted into high-value-added industrial chemicals using different green processing technologies with the aim of reducing wastes deposited in the environment (Arancon et al., 2017). Several processing technologies such as physical (e.g. mechanical comminution, irradiation, microwave, ultrasonication, hydrothermal etc.), chemical (e.g. acid and alkaline hydrolysis, ozonolysis, ionic liquids, deep eutectic solvents etc.), physiochemical (e.g. steam explosion, supercritical fluid, wet oxidation etc.), and biological (use of enzymes and microbes) for biomass waste conversion into fine chemicals have previously and recently been explored. However, little or no success has been accomplished due to the recalcitrant nature of lignin posed by its tight cross-link with cellulose and hemicellulose (Ning et al., 2021). Therefore, to compensate for the problems accustomed with a single technique of biomass valorization, researchers now combine two or more pretreatment technologies with fewer shortcomings (Bhatia et al., 2021; Ning et al., 2021). This will also enhance biomass waste deconstruction, especially by focusing more on recent technologies that support lignin removal.

The various high-value industrial chemicals that can be derived from waste biomass are broadly categorized into three groups namely; sugar and sugar alcohol (e.g. glucose, arabinose, mannitol etc.); biodiesel and esters; bio-oil, bio-char, and synthetic gas, which produce downstream chemicals like alcohols, polyols, carboxylic acids, organic acids, polymers, furan, bio-gas, liquid alkanes, and amino acids. All these chemicals show diverse industrial applications especially in the field of agrochemicals, pharmaceuticals, biomedicals, food, fragrances, cosmetics, building, aerospace etc. (Ning et al., 2021).

Conclusion

The present mini-review highlights the significance and potential of lignocellulosic waste biomass for production of high-value industrial chemicals. The valorization of biomass wastes into high-value-added chemicals has drawn attention lately because of the projected decline in availability of petroleum resources (utilized for production of these industrial products via the conventional technology), as well as the unceasing increase in the amount of biomass waste generated in the environment. The high-value chemicals generated from the biomass waste have promising potential applications in pharmaceutical, agrochemical, food, and cosmetic industries, thus they are worthy of recovery. However, the currently available waste valorization technologies face various challenges ranging from cost and energy ineffectiveness to process inefficiency and environmental unfriendliness. Hence, further research on improving the existing biomass conversion technologies to become a green sustainable approach for valorization of our ever increasing biomass waste is paramount.

References

Arancon, R. A. D., Lin, C. S. K., Chan, K. M., Kwan, T. H. & Luque, R.(2017). Advances on waste valorization: new horizons for a more sustainable society. In Waste Management and Valorization (pp. 23-66). Apple Academic Press.

Bhatia, R. L., Lad, J. B., Bosch, M., Bryant, D. N., Leak, D., Hallet, J. P. & Gallagher, J. A. (2021). Production of oligosaccharides and biofuels from Miscanthus using combinatorial steam explosion and ionic liquid pretreatment. Bioresource Technology, 323: 124625.

Cho, E. J., Trinh, L. T. P., Song, Y., Lee, Y. G. & Bae, H. J. (2020). Bioconversion of biomass waste into high value chemicals. Bioresource technology, 298: 122386.

Clauser, N. M., Gonzalez, G., Mendieta, C. M., Kruyeniski, J., Area, M. C. & Vallejos, M. E. (2021). Biomass waste as sustainable raw material for energy and fuels. Sustainability, 13(2): 794.

Gumisiriza, R., Hawumba, J. F., Okure, M. & Hensel, O. (2017). Biomass waste-to-energy valorisation technologies: a review case for banana processing in Uganda. Biotechnology for biofuels, 10(1): 1-29.

Ning, P., Yang, G., Hu, L., Sun, J., Shi, L., Zhou, Y. & Yang, J. (2021). Recent advances in the valorization of plant biomass. Biotechnology for Biofuels, 14(1): 1-22.

Yin, X., Wei, L., Pan, X., Liu, C., Jiang, J. & Wang, K. (2021). The pretreatment of lignocelluloses with green solvent as biorefinery preprocess: a minor review. Frontiers in Plant Science, 12: 670061.

Zhang, J., Wang, Y., Du, X. & Qu, Y. (2020). Selective removal of lignin to enhance the process of preparing fermentable sugars and platform chemicals from lignocellulosic biomass. Bioresource Technology, 303: 122846.

Zhou, C. & Wang, Y. (2020). Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Science and Technology of Advanced Materials, 21(1): 787-804.

Dr. Haliru Musa is a Lecturer II in the School of Science and Information Technology, Department of Biological Sciences, Skyline University Nigeria. He acquired his PhD in Bioprocess Engineering from Universiti Malaysia Perlis, Malaysia

You can join the conversation on facebook @SkylineUniversityNG and on twitter @SkylineUNigeria